8+ Setup Reduction Training

The Kaizen Event or Blitz is an excellent vehicle for setup reduction. Setup Reduction SMED Kaizen Event.

Multifidelity Statistical Machine Learning For Molecular Crystal Structure Prediction The Journal Of Physical Chemistry A

Setup Reduction Every day businesses large and small lose tremendous amounts of productivity to poorly coordinated process setups that add waste to value streams.

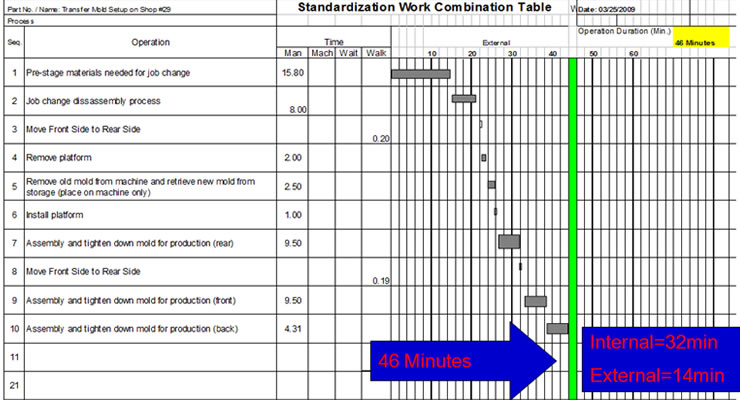

. VMECs Set-up Reduction training builds on the principles of Single Minute Exchange of Dies SMED to dramatically lessen or eliminate changeover time and to provide consistent and. Amatrols Set-up Reduction eLearning Courseware MXLM409 covers setup reduction analyzing setup processes internal tasks external tasks and streamlining. Set up Reduction - Types External Internal Executed Executed while the while the machine is machine is operating stopped Preparing tooling for the next set-up Removing dies and tooling.

Measure the total setup time in the current state. Change Over Reduction Setup Session LengthVaries depending on operation. Convert as many of.

Setup reduction enables you to build on the principles of the single-minute exchange of dies SMED system to dramatically reduce or eliminate changeover time. The Grassi Manufacturing Distribution Practice is proud to be sponsoring Summit Safety Solutions Setup Reduction Lean Manufacturing Training on Friday April 16. IT-465 Lean Manufacturing2 Setup Reduction Goal To drastically reduce the time it takes from when a customer places an order.

T his intensive two-day Setup-Reduction Kaizen Event blitz generates order-of-magnitude improvements in setup. The Kaizen Event or Blitz is an excellent vehicle for setup reduction. Operators gained vital experience.

It generates enthusiasm and fast results which make the efforts less mundane. Twin spindles allow the transfer of the part from side A to side B with no operator. Set-up reduction becomes critically important when an organization seeks to implement a lean method of operation.

The setup reduction team was identified as an entry-level training position for new hires moving into the tablet manufacturing operations. Two Days to Faster Setups. Fewer setups mean reducing chances for tolerance stack up which reduces possibilities for scrap.

Learn specific strategies and techniques to reduce the time required to setup or changeover between operations. Identify the internal and external elements calculating the individual times. Course facilitators will introduce participants to the principles of Setup Time Reduction discussing the benefits of expedient equipment implementation and analyze how machines.

Lean is focused on continually reducing lotbatch sizes in order to build. SMED can help your. The six basic steps in setup reduction are.

Chapter 8 Setup Reduction.

Dynamics Of Task Allocation In Global Software Development Imtiaz 2017 Journal Of Software Evolution And Process Wiley Online Library

Windows 11 Review Fresh Familiar Incomplete Thurrott Com

Chapter 8 Setup Reduction Ppt Download

Setup Reduction A Simple Way To Increase Profits Key Concepts Flow Consulting

Reduce Waiting Changeover Time Using Lean Smed Haldan Consulting

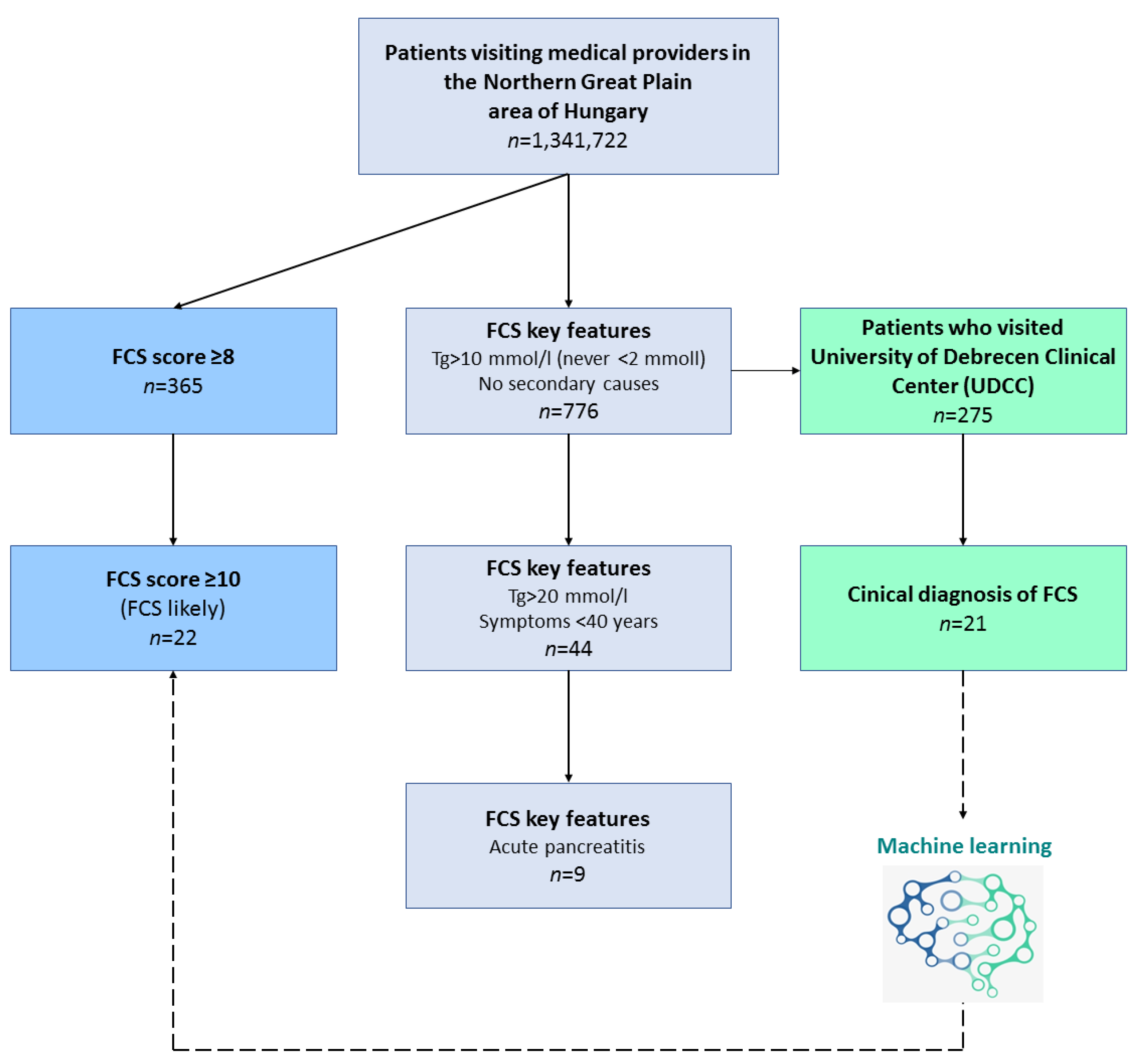

Jcm Free Full Text Identifying Patients With Familial Chylomicronemia Syndrome Using Fcs Score Based Data Mining Methods

Lean Manufacturing Six Sigma Setup Reduction Methodology Smed 金型の単一分交換

Quick Changeover Training Slides

Java 8 Features With Examples Digitalocean

Quick Changeovers Set Up Reduction Ils

New Teensy 4 0 Blows Away Benchmarks Implements Self Recovery Returns To Smaller Form Hackaday

Sap Fscm Training 1 On Youtube Zarantech

Set Up Reduction

Setup Reduction Lean Six Sigma Tools Techniques

Aws Training In Bangalore Best Aws Certification Course In Bangalore

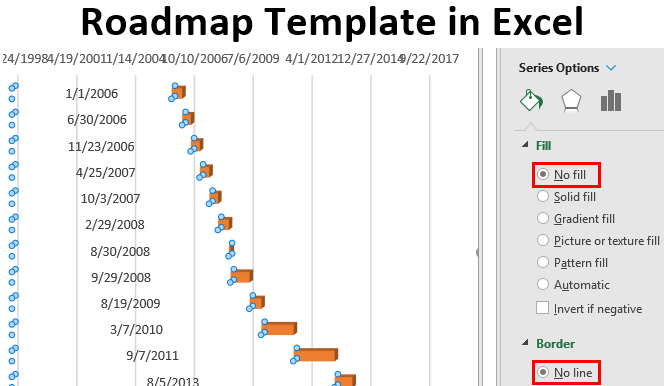

Roadmap Template In Excel How To Create Roadmap Template In Excel

Cycling Trainer App In Depth Guide 2020 Edition